Guangzhou, Guangdong Apr 1, 2025 (Issuewire.com) - As global industries shift toward smart factories and intelligent production lines, KLARM Precision Machining is making a major push to support this transformation. The company has announced a significant expansion of its operations and capabilities to meet surging demand from the manufacturing automation sector, which now plays a central role in modern industrial development across the world.

With decades of experience in precision CNC machining, KLARM is ramping up its services to meet the exacting needs of manufacturers producing automated machines, robotics systems, sensor platforms, linear motion equipment, and intelligent factory hardware. The companys newest investments in technology, workforce development, and process automation will allow it to better serve clients across industries such as automotive, medical, logistics, aerospace, consumer electronics, packaging, and food processing.

As industries embrace Industry 4.0 and smart manufacturing, companies building the hardware behind automation are experiencing exponential growth. These manufacturers rely on suppliers who can deliver high-precision, high-complexity machined components on time and within specificationespecially as lead times shrink and product development cycles accelerate.

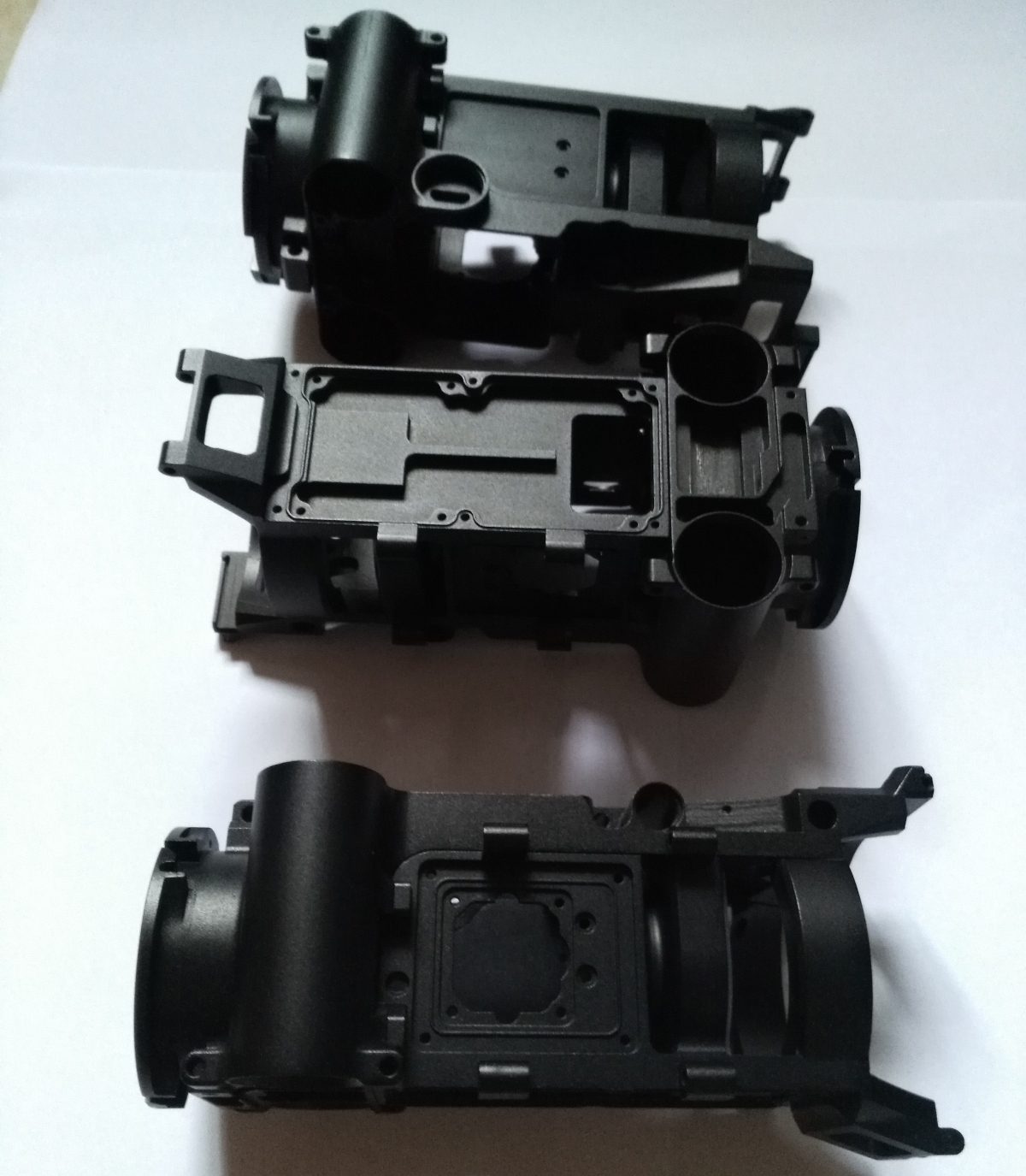

KLARM is seeing increased demand for parts such as: Robotic arm joints, gears, and motor mounts, Actuator bodies and linear rail housings, Precision spacers, fasteners, bushings, and guide pins, Sensor enclosures, mounting brackets, and connector housings, Custom aluminum frames, control panel housings, and base plates.

"The shift toward automated manufacturing is reshaping how factories function around the world," said Jacky, CEO of KLARM. "We recognize that behind every robotic cell, every conveyor system, and every smart inspection station, there are hundreds of precision-machined components in China. We're fully committed to supporting this movement."

KLARM has added a new suite of multi-axis CNC machining centers, including 5-axis machines for complex and multi-face parts, Swiss-type CNC lathes for miniature, high-tolerance components, and Horizontal and vertical machining centers for large flat parts and production-level work.

These machines have boosted KLARMs daily output, reduced cycle times, and enabled simultaneous prototyping and full-scale production, allowing the company to serve clients at all stages of development.

KLARM is actively expanding its technical team, hiring automation-focused mechanical engineers, CAM programmers, and quality inspectors. Internal training programs ensure that team members are equipped to understand customer-specific tolerances, GD&T standards, and the mechanical interfaces common in automation systems.

More On Scoop24x7 ::

- Angelina Aleman, Recognized by BestAgents.us as a 2025 Top Agent

- Megan Gillette: Your Trusted Real Estate Broker in Champaign, IL

- Blockchain Messengers: Transforming the Future of Communication

- nGEL kick-off meeting: redefining power, heating, and cooling

- Viktor Shvets, Recognized by BestAgents.us as a 2025 Top Agent

New CMMs (Coordinate Measuring Machines), optical scanners, and in-line measurement tools allow for: 100% inspection of high-value automation parts, Real-time quality assurance for large-volume production, and Certification-ready documentation for critical assemblies.

KLARM is already collaborating with a growing number of automation equipment manufacturers, robotics integrators, and industrial technology startups to supply high-performance parts for: Collaborative robots (cobots) and industrial arms, Automated packaging and inspection systems, Custom jigs, nests, and fixtures for assembly lines, Intelligent conveyors, indexing tables, and pick-and-place machines, Medical automation systems and laboratory robotics.

These companies rely on KLARM for short lead times, responsive engineering support, and the flexibility to deliver both one-off prototypes and high-volume production runs.

"Many of our customers are developing breakthrough technologies in automation," said Jacky. "They need partners who understand the urgency of iteration, who can machine highly complex parts, and who can scale up quickly as their products go to market. KLARM is built to meet those needs."

KLARM supports the machining of a wide range of materials critical to automation systems, including: Aluminum alloys (6061, 7075) for lightweight structural parts and enclosures, Stainless steel (304, 316, 17-4PH) for corrosion-resistant shafts, pins, and frames, Engineering plastics (Delrin, PEEK, nylon, ABS) for sensor mounts, bushings, and electronic housings, Brass and copper for electrical contacts and connector parts, Tool steels and hardened alloys for wear-resistant and high-load parts.

The company offers tight tolerances (±0.01 mm), surface finishing (anodizing, powder coating, polishing), and secondary assembly services, all essential for automation applications.

KLARM views its growth in the manufacturing automation sector as a core pillar of its long-term vision. The company is working toward Achieving ISO 9001 and ISO 13485 certifications, developing automation-specific supply chain partnerships, expanding its digital quoting and order tracking systems for easier customer interaction, and participating in global automation expos and technology conferences to stay at the cutting edge.

"We believe that smart automation is not a trendit's the foundation of modern manufacturing," said Jacky. "KLARMs mission is to be a behind-the-scenes enabler, delivering the precision and reliability our customers need to build the factories of the future."

KLARM Precision Machining is a leader in high-quality CNC machining services in China, including prototyping and small- to medium-batch production. For over 20 years, KLARM has served clients in aerospace, automotive, medical, robotics, energy, and automation, delivering components that meet the highest standards of precision and reliability. With a combination of advanced equipment, technical expertise, and commitment to customer success, KLARM supports companies from product concept through to full-scale manufacturing.

Media Contact

Klarm Group Limited

Lanny Larm

Panyu, Guangzhou, Guangdong, China

Source :Klarm Group Limited

This article was originally published by IssueWire. Read the original article here.